Process Innovations at Marathon Electric

No matter how good our products, services, people, processes and performance, we are dedicated to making them better. Here are some of the things we are doing to strive for excellence in the generator industry.

|

Hyundai/KIA KBN-135 CNC Boring Machine

Marathon Electric started production on 9/14/07 on the new Hyundai/KIA KBN-135 CNC Boring equipment that was installed in August 2007. The primary function of this innovative new equipment will be body machining of 740F and 1000F generator product. It allows Marathon the flexibility to bring large generator machining in-house and make the product more cost effective. The machine improves the quality of the product by using state-of-the-art machining techniques that enhance the manufacturability of the product and provide the customer with the continuing quality Marathon is famous for world-wide.

|

|

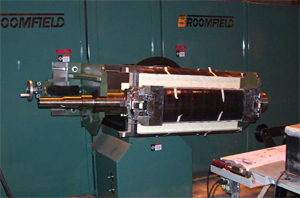

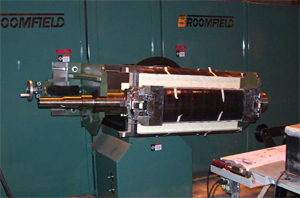

Broomfield Rotor Winder

Marathon Electric, in an effort to provide better delivery times and customer service, has installed a new Broomfield M-900 cantilevered generator rotor winder dedicated to 740F product. The equipment reduces changeover time of the previous rotor winder and provides a much needed increase in throughput on the winding line. Increased safety through the use of light curtains and automated controls and functions add to the benefits of this equipment.

|